Tempo 2.0 - Section 3.3 Value Streams and Process Flows

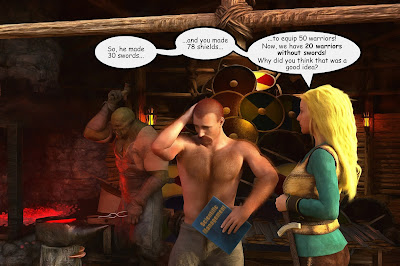

…that the greatest prosperity can exist only as the result of the greatest possible productivity of the men and machines of the establishments— that is, when each man and each machine are turning out the largest possible output. — The Principles of Scientific Management , by Frederick Taylor, 1911. The 20th century was a century of economic growth and technological development never seen before in the history of humanity. A significant part of the credit for this has to go to Frederick Taylor, whose book The Principles of Scientific Management, was published in 1911. Taylor laid down the basic principles of mass production. The ideas worked well for many years, but there were hidden problems. One thing that happened, because the idea was that each worker and each machine should produce as much as possible as much of the time as possible, was that parts tended to pile up, everywhere. Different people, and different machines, doing different things, produce things at different rat...